Branches

{{ load_row_data(desktop_selected1).title }}

{{ load_row_data(desktop_selected2).title }}

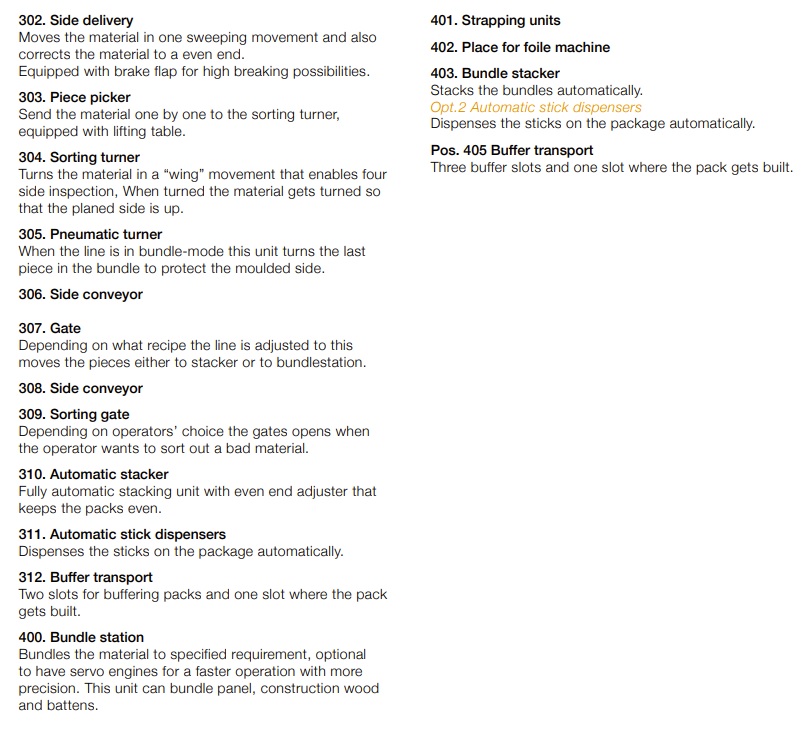

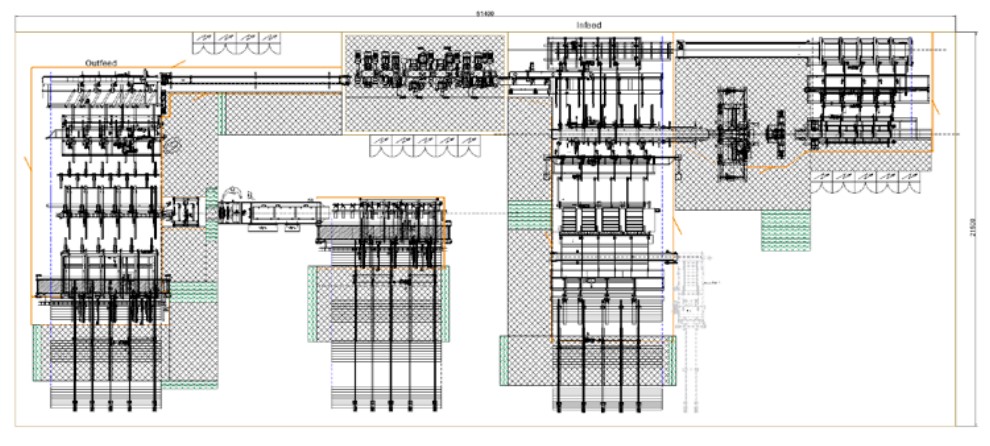

Developed to run products that require bundling, the handling to the resaw makes it especially good for panel even though its name the line can handle battens and construction wood as well. Much like the LFC250 the whole line is tuned and operated by panels that makes it easy for the operator to change timings and speeds on the line with savable recipes for your different products. The bundle unit that is the heart in the line has been developed over many ears and is constantly getting upgrades in the same pace as the technology advances. The latest development that is a option is that some parts are switched from pneumatic to servo-motors. All the well-known units in the line for example tilt, elevator and stacker are units that is reliable and all spare parts are ready and available from the System Hall HQ.

| Line for Panel 250 | |

|---|---|

| Pieces per minute | 60p/m |

| Length | 1,8 – 6 m |

| Max width | 245 mm |

| Min width | 50 mm |

| Max thickness | 100 mm (Not when bundling) |

| Min thickness | 9 mm |

| Packet size (infeed) | 1,2 x 1,2 m |

| Packet size (outfeed) | 1,2 x 1,2 m |

| Max pack weight | 4000 kg |

| Color frame | RAL 1015 |

| Color moving parts | RAL 2004 |

|

| Line description | |

|---|---|

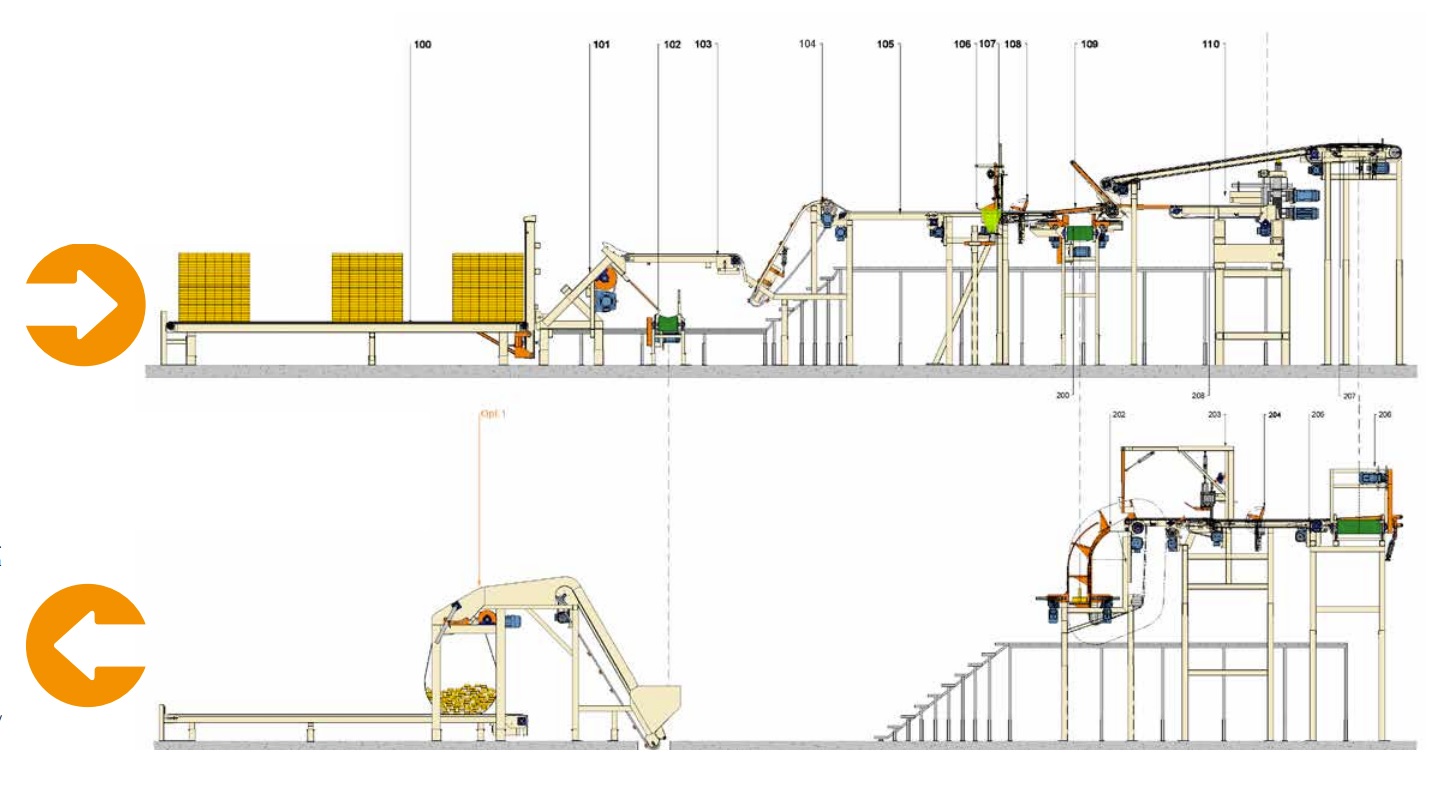

| Infeed | |

|

|

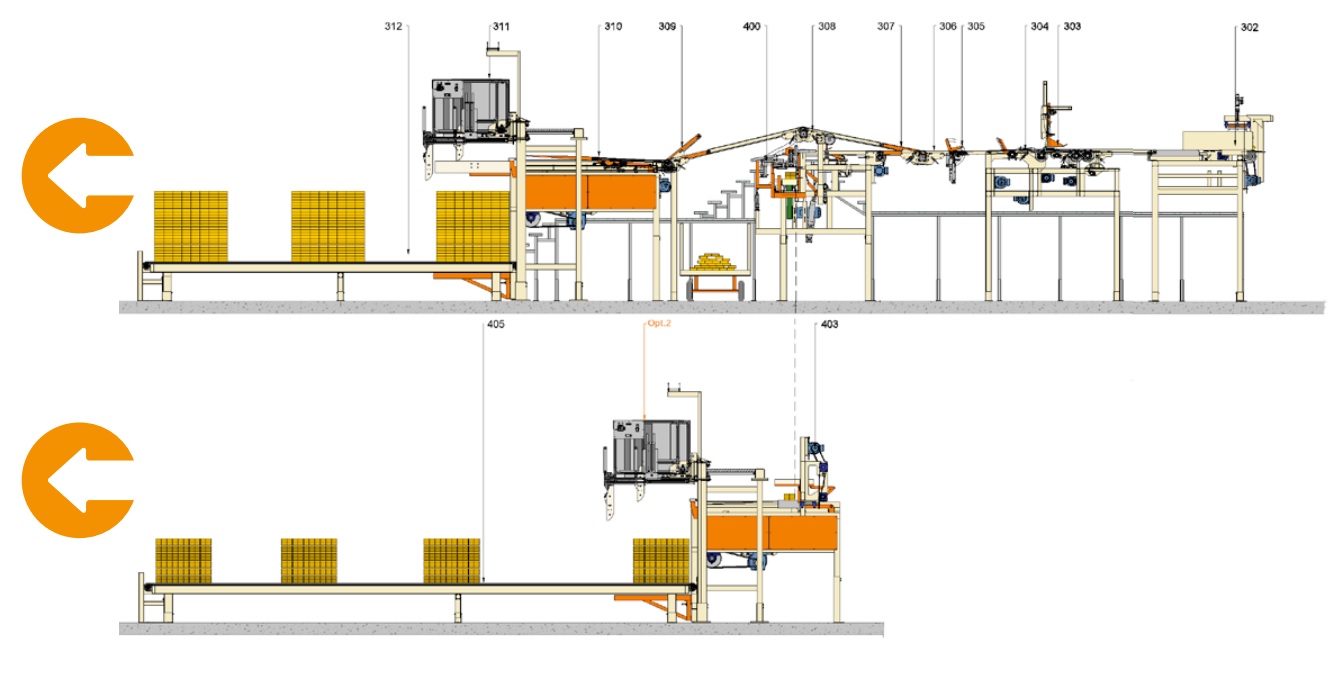

| Outfeed | |

|

|

|

|