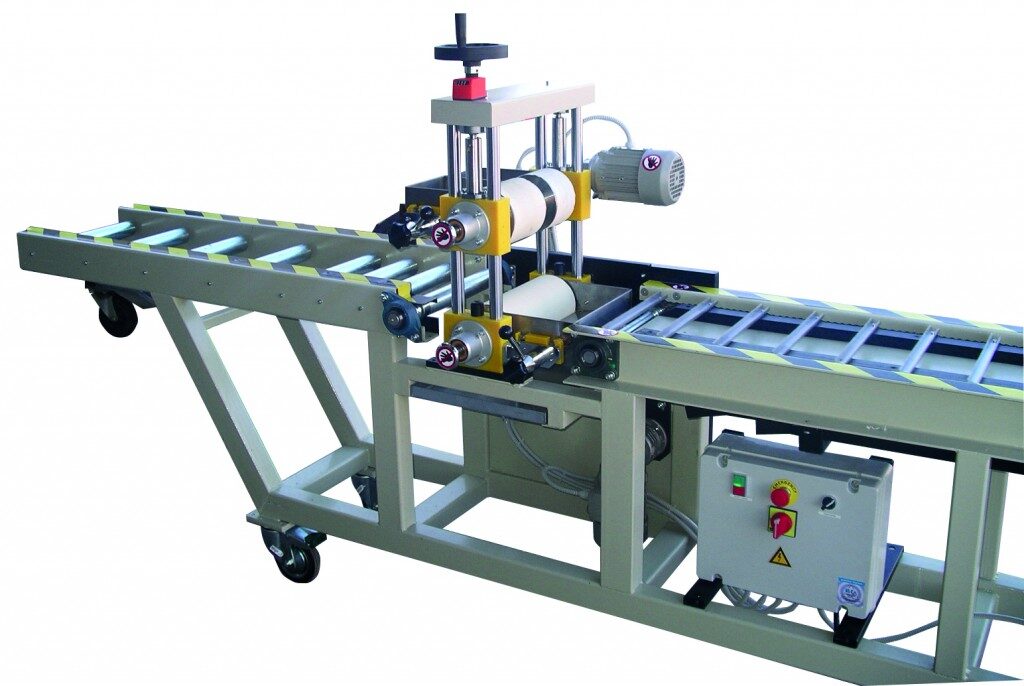

PVA glue application device GA-DT on frame. With wheels.

Trimwex gluing device GA-DT is designed for double-sided gluing of flat materials.

Glue rollers can apply glue to both the upper and lower surfaces of the material. If necessary, for example, the lower glue roller can be removed and PVA glue can be applied only to the upper surface of the material.

The gluing device is on a base frame on wheels, so it can be moved to another workplace if necessary.

The standard solution is a non-driving 1.5m roller conveyor in front of the gluing device and a 1.5m long non-driving disc conveyor on the outfeed side.

If necessary, the gluing device can be modified with an automatic feed conveyor and an automatic receiving conveyor (disc conveyor or “U” profile cross conveyor)

If necessary, an additional feed roller can be placed before the gluing device to facilitate the passage. If necessary, the double-sided gluing device can also be replaced with a single-sided gluing device.

With the glue rollers of this solution, EPI glue can also be dosed. This requires an additional EPI adhesive and hardener pumping and dosing system.

If you need a fully automatic magazine gluing line, please let us know. We will make you an offer based on your material data.

Description

| GA-DT | |

|---|---|

| 1. Infeed non driven roller conveyor: | |

| – for length: | 1500 – 3000 mm |

| 2. Glue applicator: | |

| – working width | 200 – 600 mm |

| – glue application rolls diameter | 2 x 140 mm |

| -speed | 20 m/min |

| – opening max. | 120 mm |

| 3. Outfeed- non driven disk conveyor: | 1500 – 4000 mm |

| – for length: |