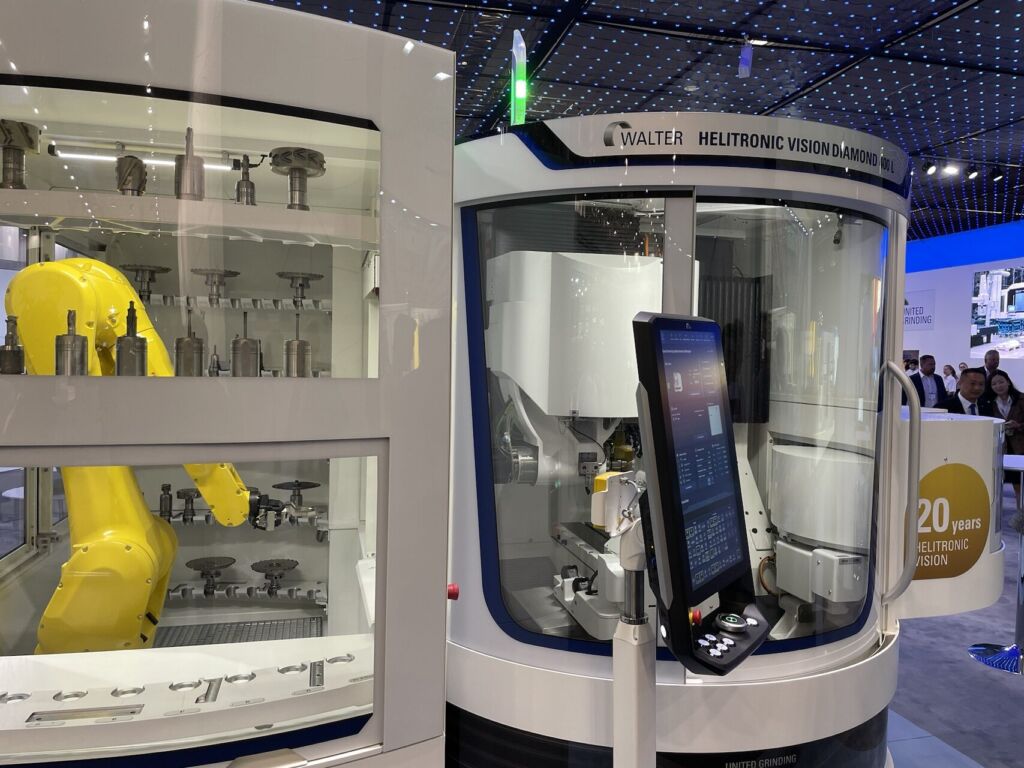

One of the top models of MTG EESTI OÜ’s German partner Walter Maschinenbau GmbH – HELITRONIC VISION DIAMOND 400 L with C.O.R.E. technology is designed for the production and resharpening of diamond cutting tools and classical cutting tools with complex geometry.

Tool diameter D= 3 – 315mm, tool length up to L=420mm and workpiece weight up to 50kg.

Processable materials in electro eroding machining: PCD / CBN

If the machine uses the special dielectric Oelheld IonoGrind (which is also a product offered by MTG EESTI OÜ), the machine can perform both conventional high-speed steel/carbide material processing of steel materials with a grinding wheel and electro eroding machining of strong materials (PCD / CBN, …) with an erosion wheel. In this case, the machine’s cutting-coolant filtration system must be equipped with an additional magnetic separator for the separation of metal parts and additional fine filters.

The machine can be additionally equipped with a LASER CONTOUR CHECK measuring device, which allows you to measure the cutting tool directly on the machine.

The machine is designed for a company producing cutting tools. It is also suitable for larger sharpening companies and metalworking companies that have special requirements for the accuracy class and a large volume of cutting tools.

Walter Maschinenbau GmbH is one of the world’s leading manufacturers of cutting tool production and regrinding equipment.

Along with Walter, the Uniteg Grinding Group also includes another cutting tool grinding equipment manufacturer – EWAG

Read more:

Walter Maschinenbau

Walter

EWAG

EWAG